Line Boring

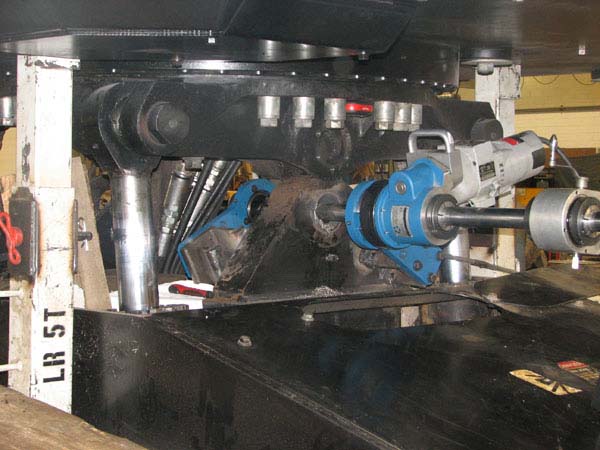

Line Boring is a precision process of aligning or realigning center-line bores on equipment and machinery. to eliminate wobbles, vibrations and/or potential equipment failures.

Heavy machinery goes through intense wear—especially at pivot points. As pin and bushing bores become oversized or misaligned, equipment can become unsafe and inefficient. As most machine operators and owners know, even with the best of care, machinery pin and bushing bores can wear out. It is especially common in high load hinge points like those found on heavy machinery and construction equipment, making the rebuilding of pin and bushing bores an on-going maintenance repair.

At Northern Iron Works, I offer professional line boring services that restore equipment to factory tolerances.

Line Boring Services

- Bore welding and machining to restore worn holes

- Pin and bushing hole resizing

- Bore sleeve installation

- Center-to-center bore alignment

- On-site and shop repairs for excavators, loaders, dozers, and more

Benefits of Line Boring

- Reduce Equipment Downtime

- Save on Costly Replacement and Repairs

- Extend Equipment Lifespan

- Return to Factory-Grade Precision

Equipment Services

- Excavators, backhoes, loaders

- Dozers and track machines

- Forestry and logging equipment

- Agricultural tractors and implements

- Custom and specialty machinery

Most line boring jobs can be completed in one day depending on the number of bores and the condition of the equipment.

In many cases, I can perform the service with minimal disassembly.

Northern Ironworks in Montana, performs line boring repairs on buckets, booms, sticks, articulation joints and more.

Contact Northern Ironworks for more information and availability.